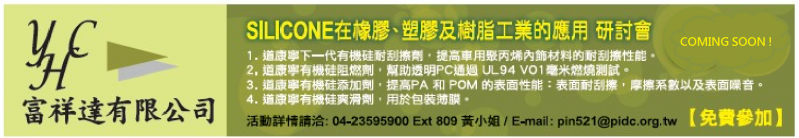

1. Dow Corning silicone additives solutions for Halogen Free Flame Retardancy (HFFR) Wire & Cable applications

2. Dow Corning Silicone Flame Retardant Helping Pass UL 94 V0 @1mm for Transparent PC

3. Dow Corning Silicone elastomer light diffusers for LED general lighting

4. Dow Corning Silicone Additives Improving PA and POM Surface Properties: Scratch

5. Dow Corning Next Generation Scratch Additives for Scratch Improvement of Auto Interior Talc Filled Polypropylene Parts

6. Dow Corning silicone Masterbatch as Slip Agent for PE film for form-fill-seal (FFS) packaging and laminate

Dow Corning silicone additives help wire & cable formulators to reduce torque & die drool and to enhance MDH & ATH dispersion and to improve surface property and flame retardancy; Also, Dow Corning next generation silicone additives for Automotive PP interior give the best combination of properties including excellent scratch, long term heat and UV stability, scratch durability, low fogging, and low VOC generation. In addition, Dow Corning new silicone flame retardant helps meet the UL 94 V-0 flammability standard for clear PC formulations at 1mm and presents minimal-to-no effect on a PC’s optical or mechanical properties. As well, Dow Corning silicone additives can help PA and POM to improve surface properties from aspects of scratch resistance, coefficient of friction (COF) and surface noise with less effect on mechanical properties; And, Dow Corning silicone elastomer LED light diffuser impart high efficient diffusion performance and differentiated optical effects from other light diffusers; Lastly, Dow Corning silicone masterbacth can reduce the coefficient of friction (COF) of PE film in high-speed form-fill-seal (FFS) packaging and laminate. This advanced silicone-based formulation was developed as an alternative to organic additives, whose slip performance is known to degrade over time and at elevated temperatures.

105150720-富祥達(dá)-邀請卡-2.pdf

105150720-富祥達(dá)-邀請卡-2.pdf 105150720-富祥達(dá)-edm.pdf

105150720-富祥達(dá)-edm.pdf